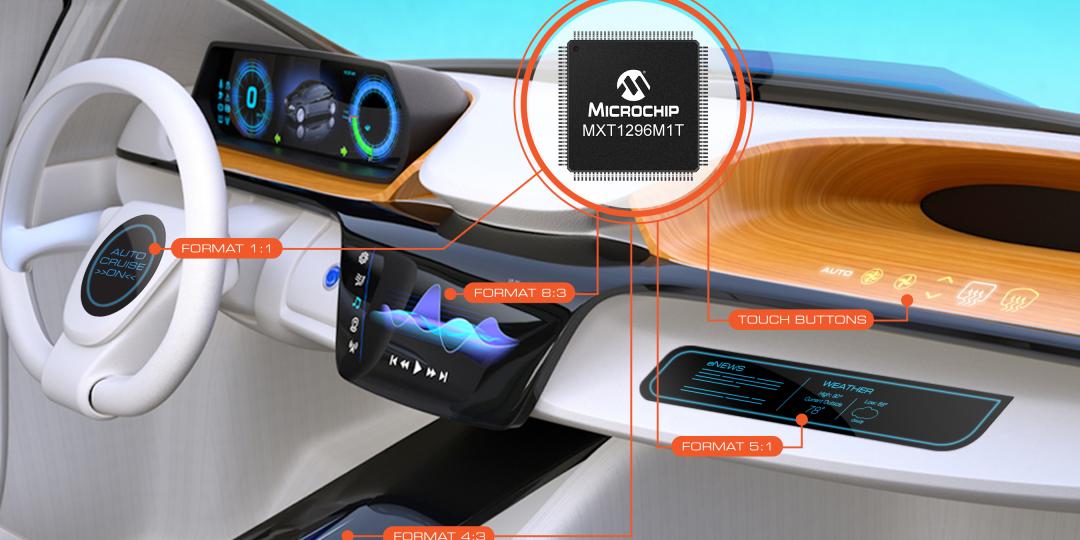

Many automotive and industrial touch HMI designers are looking to merge the benefits of a mechanical rotary encoder input with the flexibility of modern multi-touch displays. Microchip Technology announced the maXTouch® Knob on Display™ (KoD™) controller as the first automotive grade touchscreen controller family to natively support the detection and reporting of capacitive rotary encoders, as well as mechanical switches on top of a touch panel. Unlike traditional mechanical rotary encoders, this new technology enables the mounting of the knob directly onto the display without an opening in the panel or any customisation of the touch pattern, increasing design flexibility and system cost savings.

The KoD technology eliminates the need for custom touch sensor patterns, providing designers the ability to easily implement a different knob count, shape and position to accommodate a variety of end-user products. The customised configurations are adjustable without changing the embedded firmware of the maXTouch KoD touch controller, leading to a faster and more flexible development cycle. The controller allows designers to keep the comfort of a rotary encoder input device but combine it with a modern and innovative interior design using smart surfaces and multi-touch displays.

An added benefit designers can expect to experience is the ease of building a sealed human machine interface (HMI) module, which is increasingly popular for in-home appliance and industrial applications. Using a knob on a display will also increase safety for the end user, for example, they won’t need to look at the display while driving to adjust their sound or air conditioning.

“Modern user interfaces commonly use multi-touch displays, removing mechanical keys for cutting-edge designs. Yet, functions like temperature or audio volume remain best controlled though a rotary encoder,” said Clayton Pillion, vice president of the human machine interface business unit at Microchip Technology.

“The new technology offers the benefits of both worlds by providing the support of a capacitive rotary encoder with a turn-key touch controller family and a comprehensive suite of dedicated tools for a fast implementation.”

With the release of the maXTouch KoD family, Microchip offers two variants to allow customers the design freedom and flexibility to choose how they will implement the capacitive rotary encoder. The KD variant enables customers to choose their knob design partner and create their own solution using a reference design jointly developed with BNL Bearings—offering the option to fully customise the design for specific applications.

The additional MK variant supports the Magic Knob™ developed by Panasonic Industry Co., Ltd. While keeping the flexibility to be mounted on standard touch sensor patterns, the Microchip Panasonic Magic Knob (MPMK) solution provides a high level of customisation for rotation and push haptic feedback, as well as for the top cover material selection.

Microchip provides a comprehensive suite of both hardware and software development tools to shorten the development cycle with a capacitive rotary knob.

- Hardware:

- ATEVK-MXT2912TDAT-A: 15.6” / ATEVK-MXT2113TDAT-A: 13.3” OGS touch panel kit including development board with USB bridge

- Capacitive rotary encoder knob reference design with 30 detents and push functionality.

- Software:

- maXTouch® Studio (IDE - development tool) with dedicated KoD family plug-ins for knob design and parameter settings